Sustainability

At SIXINCH, we believe that design should never reach an end point. Every product we create is built to come back to us — ready for a new life. With 98% recyclability, zero overstock, and material recovery built into our DNA, we are shaping a future where furniture is as flexible as imagination.

OUR VISION

Circularity at Sixinch is not just about recycling.

It’s about designing intelligently, producing responsibly, recovering materials and extending product life in every possible way.

Rebound foam: our circular raw material

Since 2022, we’ve expanded the use of REBOUND foam — created from:

mattress foam offcuts

shredded foam scraps

post-consumer Sixinch furniture

production leftovers

Why this matters:

Same performance as new foam

Multiple density options available

Every leftover piece gets a second life

Bringing us closer to true zero waste manufacturing

Our impact in numbers

RECYCLING PROCESS

Product Return

An old Sixinch piece is returned to our factory. The foam skin is removed. Any foam too small or damaged is shredded for rebound foam.

Skin Removal

The outer foam skin is carefully removed so the structural foam block can be reused efficiently.

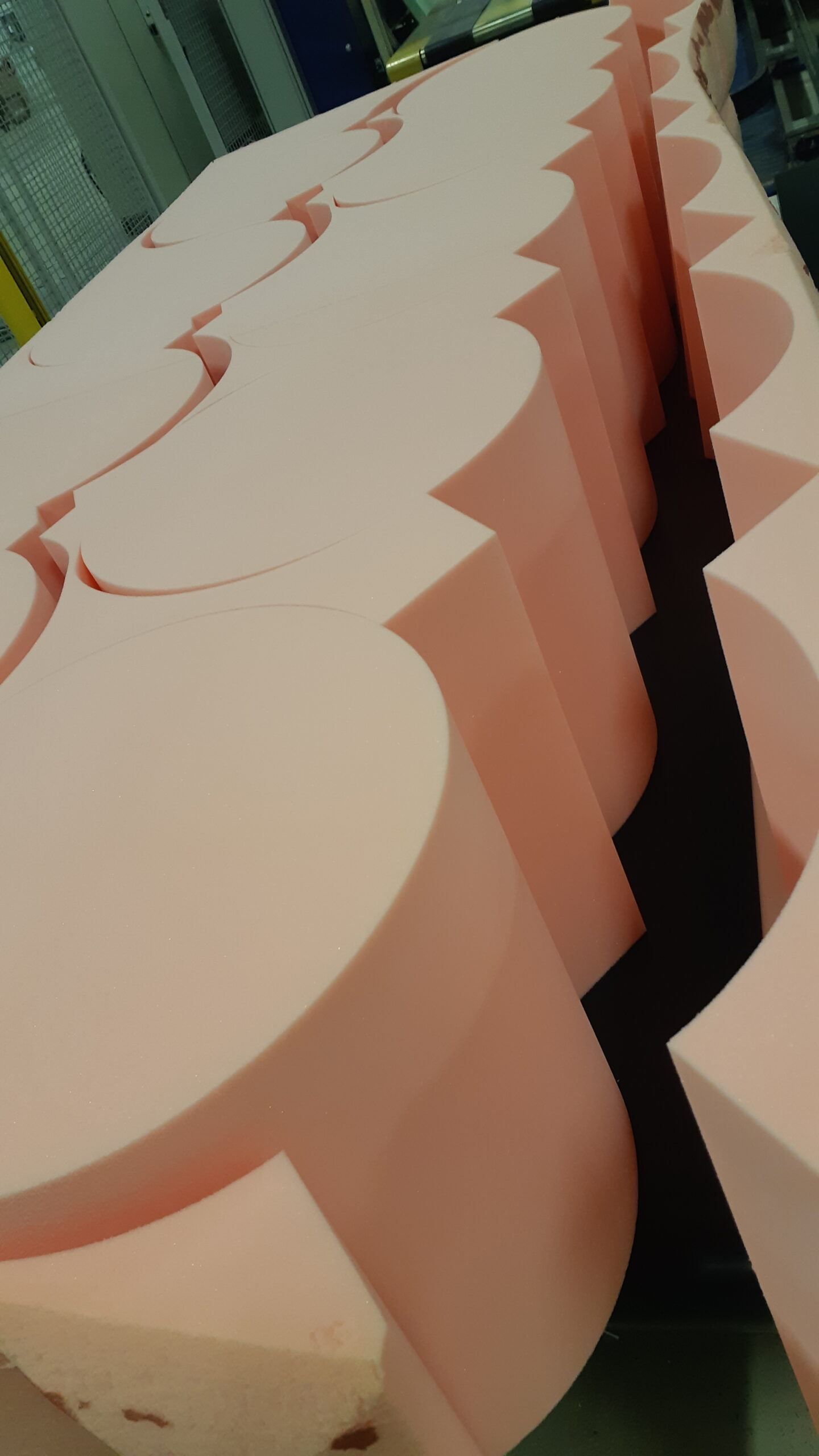

Shaving & Preparation

The recovered foam block is shaved and straightened, creating clean surfaces for CNC cutting with maximum material yield.

CNC Cutting

Digital design files are loaded and CNC machines cut new shapes from the recovered foam block.

Rebound Foam Production

All leftover cut-off pieces are shredded into rebound foam. Only the foam skin remains — and we are testing solutions to recycle it into molded forms.